CCTV & PACP Reporting

Find Out The Remaining Usefulness Of Your Pipe with MSI Technology

Our approach to large diameter pipe assessment at SewerVUE is anchored in the integration of advanced inspection techniques, including CCTV (Closed-Circuit Television) Inspection and PACP (Pipeline Assessment and Certification Program) Inspection. These methods combine to offer an in-depth understanding of your pipeline's condition, allowing you to make informed decisions for maintenance, rehabilitation, and long-term infrastructure reliability.

CCTV Inspection

This section of our assessment process grants you access to visual records captured during the inspection. With real-time footage at your disposal, you can gain a firsthand view of the conditions within the pipeline. It's a powerful tool that lets you see precisely what's happening within the pipe, making it easier to identify immediate issues, such as blockages, structural damage, or sediment buildup. The visual component adds a layer of transparency to the inspection process, enhancing your understanding of your pipeline's health.

PACP Inspection

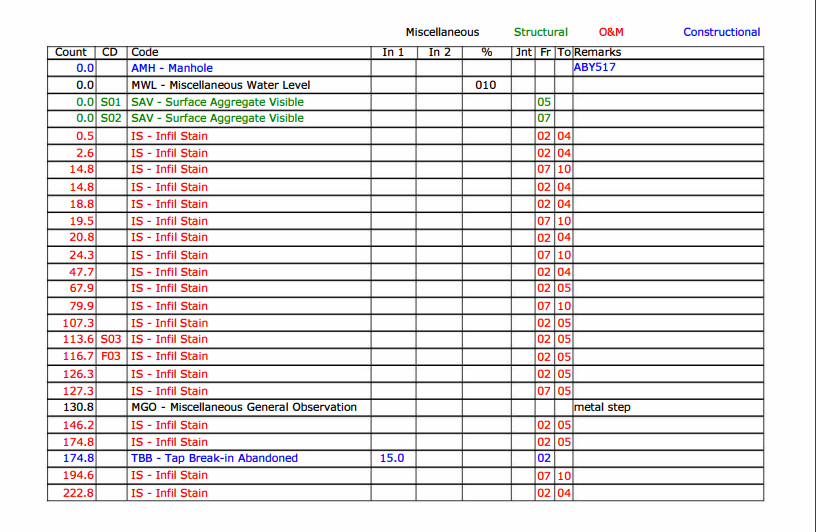

Our detailed pipeline assessments include the assessment of two key defect categories: structural and operational and maintenance (O&M). The assessment is based on a variety of parameters that help us create a comprehensive picture of your pipeline's condition. This includes:

Pipe Rating (OR): The Pipe Rating is a metric that quantifies the condition of your pipe based on the number and severity of defects found during the survey. A higher rating indicates a greater number of defects or more severe issues. This rating is calculated separately for both structural and operational and maintenance defects, allowing you to prioritize and address issues effectively.

Pipe Rating Index (RI): The Pipe Rating Index provides an average condition grade of the defects identified during the survey. The scale ranges from one to five, with five signifying significant defects and one indicating minor issues. This index helps differentiate whether your pipe rating is influenced by a few severe defects or a larger number of less severe ones. Like the Pipe Rating, this index is calculated separately for structural and operational defects.

Distance Measurement: We measure the distance using a rotary encoder with an accuracy of approximately +1%/-5%, ensuring precise measurements.

Condition Grades: We assign condition grades to defects in both the structural and operational and maintenance categories, using a scale from 1 to 5:

- 5: Most significant defect grade

- 4: Significant defect grade

- 3: Moderate defect grade

- 2: Minor to moderate defect grade

- 1: Minor defect grade

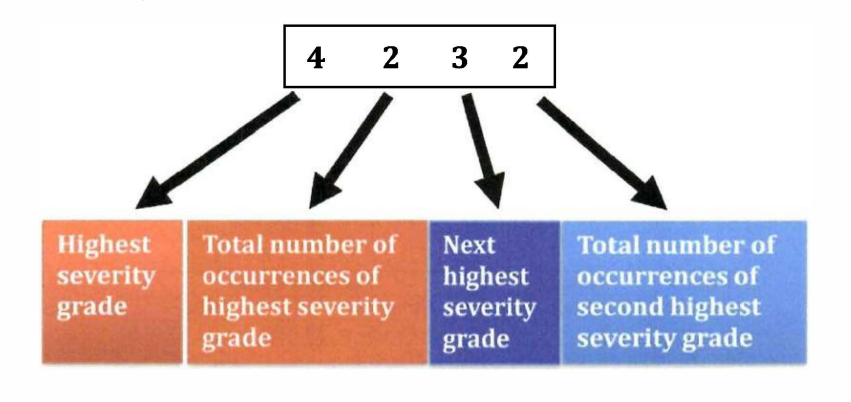

Quick Score Rating:The PACP Quick Rating offers a concise representation of the occurrence of the two highest severity grades. This four-character score provides a quick snapshot of the condition, indicating:

- The highest severity grade occurring along the pipe length.

- The total number of occurrences of that highest severity grade (with alphabetic characters used for totals exceeding 9).

- The second highest severity grade along the pipe length.

- The total number of occurrences of the second-highest severity grade (with alphabetic characters used for totals exceeding 9).

SewerVUE Technology

SewerVUE can tackle big jobs in some of the toughest places on Earth, and get actionable data quickly. Our methods are both accurate and cost-effective. By using remotely operated vehicles to gather data, these methods also eliminate the hazards of man entry surveying methods.

To discuss how SewerVUE can meet your specific needs, contact us today!